Science

Chemists Develop Innovative Technique to Create Advanced Materials

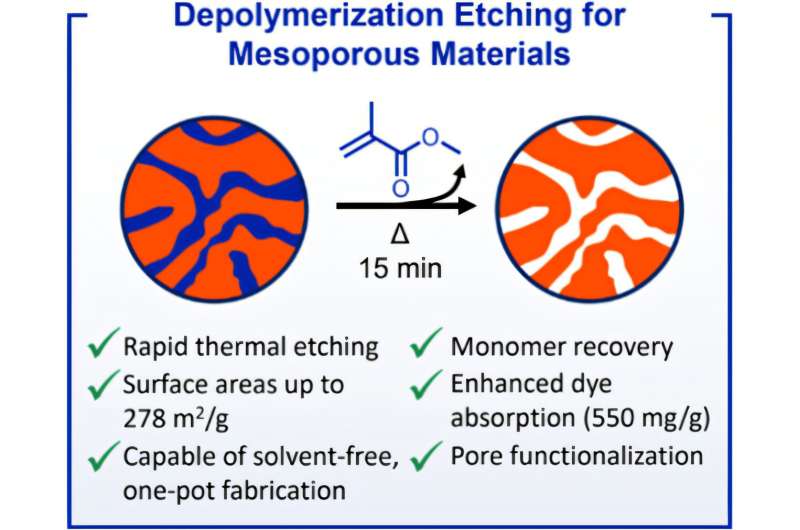

Chemists at the University of Florida have unveiled a groundbreaking technique to create highly porous materials from everyday plastics. This innovative method, which emphasizes the removal of material rather than the addition of new components, has significant potential applications in electronics, separations, and battery manufacturing. The findings were published on November 4, 2025, in the journal ACS Central Science.

The technique, likened to the process of sculpting, involves the careful removal of material to form pores within the structure. According to Brent Sumerlin, Ph.D., a professor of chemistry and the senior author of the study, “We’re sculpting from within by creating pores from inside the material, which I don’t think would be possible by any method.” This approach enables the production of materials that are in high demand for various applications, including battery technology and water filtration systems.

Sumerlin and his team leveraged their previous research on the breakdown of plastics, recognizing that different types of plastics decompose at varying temperatures. By exploiting these differences, they developed a method to create new materials. In their experiments, they combined the building blocks of Plexiglass and Styrofoam, which typically do not mix well. When subjected to the appropriate temperature, the components of Plexiglass evaporated while the polystyrene remained, resulting in trillions of minuscule pores, each smaller than a virus.

Remarkably, a single gram of the resulting material can possess a surface area equivalent to that of a full-sized tennis court. “It’s like having a very small mesh in a screen, which is potentially good for purifying wastewater,” Sumerlin noted. His team has also filed a patent application for this new technique, which could revolutionize the manufacturing of high-performance membranes essential for battery technology.

As global energy demands increase, the need for efficient methods to separate materials has become critical. The porous filters created from this method could serve multiple industries, all stemming from an initial aim to improve plastic recycling. “This just shows how basic research in one area can inform new applications in a completely different area,” Sumerlin emphasized.

Research team member Kaden C. Stevens contributed to this study, showcasing the potential for innovation through interdisciplinary approaches. The findings not only represent a significant advancement in material science but also highlight the importance of sustainable practices in addressing environmental challenges associated with plastic waste.

In conclusion, the University of Florida’s novel technique exemplifies how ingenuity in scientific research can lead to practical solutions for pressing industrial and environmental issues.

-

Science4 weeks ago

Science4 weeks agoUniversity of Hawaiʻi Joins $25.6M AI Initiative to Monitor Disasters

-

Lifestyle2 months ago

Lifestyle2 months agoToledo City League Announces Hall of Fame Inductees for 2024

-

Business2 months ago

Business2 months agoDOJ Seizes $15 Billion in Bitcoin from Major Crypto Fraud Network

-

Top Stories2 months ago

Top Stories2 months agoSharp Launches Five New Aquos QLED 4K Ultra HD Smart TVs

-

Sports2 months ago

Sports2 months agoCeltics Coach Joe Mazzulla Dominates Local Media in Scrimmage

-

Politics2 months ago

Politics2 months agoMutual Advisors LLC Increases Stake in SPDR Portfolio ETF

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Walk to Raise Mental Health Awareness

-

Science2 months ago

Science2 months agoWestern Executives Confront Harsh Realities of China’s Manufacturing Edge

-

World2 months ago

World2 months agoINK Entertainment Launches Exclusive Sofia Pop-Up at Virgin Hotels

-

Politics2 months ago

Politics2 months agoMajor Networks Reject Pentagon’s New Reporting Guidelines

-

Science1 month ago

Science1 month agoAstronomers Discover Twin Cosmic Rings Dwarfing Galaxies

-

Top Stories1 month ago

Top Stories1 month agoRandi Mahomes Launches Game Day Clothing Line with Chiefs