Science

Algorithms Illuminate Propane to Propylene Transformation Process

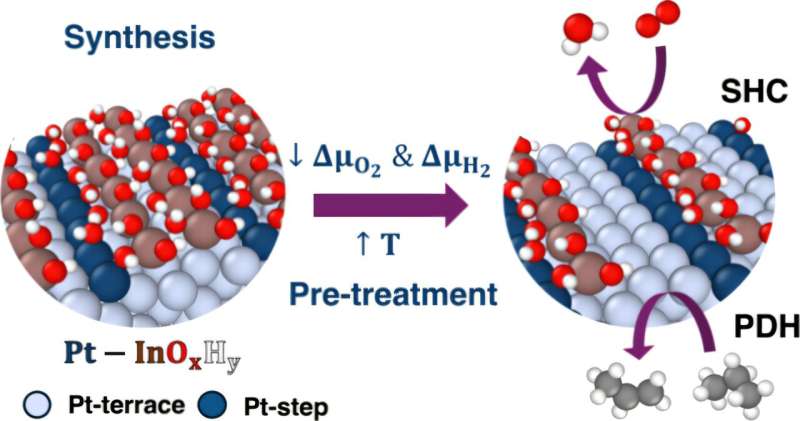

Research from the University of Rochester has unveiled critical insights into the conversion of propane to propylene, a process crucial for the production of countless everyday products, including plastic containers and outdoor furniture. This breakthrough stems from the development of advanced algorithms that clarify the atomic interactions involved in this complex chemical transformation.

Revolutionizing Industrial Chemistry

In a study published on November 13, 2025, in the Journal of the American Chemical Society, researchers demonstrated how the application of tandem nanoscale catalysts can streamline the propane-to-propylene conversion by integrating multiple reaction steps into one. While a previous study in 2021 highlighted this potential, the specific atomic mechanisms remained largely unexplored, hindering broader industrial application.

The team, led by Siddharth Deshpande, an assistant professor in the Department of Chemical and Sustainability Engineering, emphasized the need for an algorithmic approach to dissect the myriad possibilities at play within the catalytic active sites. “We refined our algorithms and used them to conduct a detailed analysis of the metallic and oxide phases driving this complex reaction,” Deshpande stated.

New Discoveries in Catalyst Functionality

Deshpande and his Ph.D. student, Snehitha Srirangam, uncovered several unexpected findings during their research. Their analysis revealed that the oxide component of the catalyst preferentially forms around defective metal sites, which is essential for the catalyst’s stability. Intriguingly, despite the varying chemical compositions of the oxide, it consistently maintained its role around these defective sites.

This understanding has significant implications for the chemical industry. Deshpande believes that leveraging these insights and the team’s algorithmic methods could enhance the efficiency of other chemical processes, such as methanol synthesis, which is used in manufacturing products ranging from paints to fuel cells.

“Our approach is very general and can open doors to understanding many processes that have remained enigmatic for decades,” Deshpande remarked. He pointed out that while the industry produces vast quantities of these chemicals, there is still much to uncover regarding the underlying mechanisms driving their production.

The potential to refine production methods could enable companies to move away from traditional trial-and-error techniques, leading to more efficient and cost-effective manufacturing processes.

This research not only contributes to the fundamental understanding of chemical reactions but also paves the way for advancements in industrial chemistry that could enhance production capabilities and sustainability across various sectors.

For further information, refer to the study by Srirangam et al. titled “Site-Selective Oxide Rearrangement in a Tandem Metal–Metal Oxide Catalyst Improves Selectivity in Oxidative Dehydrogenation of Propane,” published in the Journal of the American Chemical Society.

-

Science4 weeks ago

Science4 weeks agoUniversity of Hawaiʻi Joins $25.6M AI Initiative to Monitor Disasters

-

Lifestyle2 months ago

Lifestyle2 months agoToledo City League Announces Hall of Fame Inductees for 2024

-

Business2 months ago

Business2 months agoDOJ Seizes $15 Billion in Bitcoin from Major Crypto Fraud Network

-

Top Stories2 months ago

Top Stories2 months agoSharp Launches Five New Aquos QLED 4K Ultra HD Smart TVs

-

Sports2 months ago

Sports2 months agoCeltics Coach Joe Mazzulla Dominates Local Media in Scrimmage

-

Politics2 months ago

Politics2 months agoMutual Advisors LLC Increases Stake in SPDR Portfolio ETF

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Walk to Raise Mental Health Awareness

-

Science2 months ago

Science2 months agoWestern Executives Confront Harsh Realities of China’s Manufacturing Edge

-

Politics2 months ago

Politics2 months agoMajor Networks Reject Pentagon’s New Reporting Guidelines

-

World2 months ago

World2 months agoINK Entertainment Launches Exclusive Sofia Pop-Up at Virgin Hotels

-

Science1 month ago

Science1 month agoAstronomers Discover Twin Cosmic Rings Dwarfing Galaxies

-

Top Stories1 month ago

Top Stories1 month agoRandi Mahomes Launches Game Day Clothing Line with Chiefs