Science

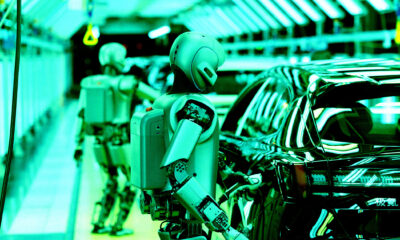

Automation Revolutionizes Welding, Painting, and Dispensing Processes

Recent advancements in automation technology are fundamentally transforming factory processes, particularly in welding, painting, and dispensing. These improvements come in response to increasing global competition, labor shortages, and heightened quality expectations in industries such as automotive, aerospace, and electronics. Manufacturers are now adopting smarter robotic systems that enhance productivity and workplace safety, leading to better process stability, faster production cycles, and reduced exposure to hazardous materials.

Advancements in Robotic Welding

The field of robotic welding has recently experienced significant technological breakthroughs. Traditional methods have struggled with challenges like part-to-part variability and skilled labor shortages. New systems now incorporate adaptive sensing, which allows for real-time adjustments during the welding process. For instance, the Fronius TPS/i Robotics system employs high-speed laser seam-tracking sensors to automatically adjust the weld torch position, compensating for variations in joint alignment.

Machine learning is also playing a critical role in optimizing welding parameters. The Lincoln Electric HyperFill system utilizes AI to analyze arc stability and bead formation, making automatic adjustments to voltage and wire feed speed. This ensures a more consistent weld quality, crucial for maintaining high standards in production.

Another notable development is the Yaskawa WeldPlus architecture, which synchronizes robotic motion with digital welding power sources. This integration minimizes arc-start delays and enhances overall welding performance, resulting in improved penetration stability.

Collaborative robots, or cobots, are making welding processes more flexible, particularly in environments that require rapid changes in production setups. The Universal Robots UR10, combined with the ReadyArc package, enables quick adjustments without halting production, catering to high-mix, low-volume manufacturing.

Innovations in Robotic Painting and Dispensing

Robotic painting processes have also evolved, prioritizing consistency and environmental compliance. The use of modern rotary atomizers and electrostatic spray guns has improved transfer efficiency and reduced volatile organic compound (VOC) emissions. For example, ABB’s RB1000 rotary atomizer enhances finish quality while minimizing waste.

With the integration of 3D vision sensors, robots can dynamically adjust their paths to accommodate complex part geometries. The Fanuc robotic paint cells are equipped with these advanced sensors, allowing for real-time adjustments based on part shape and coating behavior. Similarly, Kuka’s AI-powered quality inspection platform can identify defects and make necessary adjustments during the painting process.

In the dispensing sector, precise control over adhesive application is essential to prevent leaks and maintain structural integrity. The Nordson EFD Precision Mix and Dispense systems utilize closed-loop metering to ensure bead quality, regardless of variations in viscosity. Additionally, the Atlas Copco EBB bead-inspection system employs laser profilometers to monitor bead dimensions, enabling immediate corrections.

Robots are now capable of handling multiple materials and switching bead profiles seamlessly, as demonstrated by Scheugenpflug’s systems, which achieve mixing accuracy of ±1%. This versatility allows for continuous sealing across irregular surfaces without manual intervention.

The integration of digital twins and offline programming tools is streamlining the deployment of robotic systems. Software solutions like Omniverse and RobotStudio enable engineers to simulate robotic cells, significantly reducing commissioning times and allowing for virtual testing of new processes.

As manufacturers embrace these advancements, the role of human workers is evolving. Automation is taking over hazardous tasks, resulting in safer working environments. Many facilities are finding that robotic adoption makes welding, painting, and dispensing roles more appealing by reducing physical risks and increasing the technical responsibilities of human operators.

Overall, the shift towards automation in welding, painting, and dispensing signifies a new era defined by adaptive technologies and data-driven processes. As manufacturers invest in these systems, they are not only improving quality and throughput but also building a more resilient production ecosystem capable of managing complex product demands with fewer skilled workers.

-

Science4 weeks ago

Science4 weeks agoUniversity of Hawaiʻi Joins $25.6M AI Initiative to Monitor Disasters

-

Lifestyle2 months ago

Lifestyle2 months agoToledo City League Announces Hall of Fame Inductees for 2024

-

Business2 months ago

Business2 months agoDOJ Seizes $15 Billion in Bitcoin from Major Crypto Fraud Network

-

Top Stories2 months ago

Top Stories2 months agoSharp Launches Five New Aquos QLED 4K Ultra HD Smart TVs

-

Sports2 months ago

Sports2 months agoCeltics Coach Joe Mazzulla Dominates Local Media in Scrimmage

-

Politics2 months ago

Politics2 months agoMutual Advisors LLC Increases Stake in SPDR Portfolio ETF

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Walk to Raise Mental Health Awareness

-

Science2 months ago

Science2 months agoWestern Executives Confront Harsh Realities of China’s Manufacturing Edge

-

World2 months ago

World2 months agoINK Entertainment Launches Exclusive Sofia Pop-Up at Virgin Hotels

-

Politics2 months ago

Politics2 months agoMajor Networks Reject Pentagon’s New Reporting Guidelines

-

Science1 month ago

Science1 month agoAstronomers Discover Twin Cosmic Rings Dwarfing Galaxies

-

Top Stories1 month ago

Top Stories1 month agoRandi Mahomes Launches Game Day Clothing Line with Chiefs